On this page: Template Download Instructions What is FMEA?

In this Template

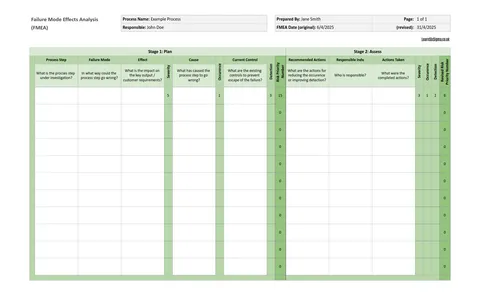

- FMEA (Failure Modes & Effects Analysis) template.

- Beautifully formatted, easy to read.

- Excel and Google Sheets formats.

- Ready to print: A4, U.S. Letter, etc.

- Ready-made columns, fields and formulas with helpful labels and descriptions.

- Comprehensive instructions and advice included.

How to Use This Template

Stage 1 — Plan

-

Complete all of the descriptive white text cells first.

-

For each process step ask "What could possibly go wrong?". Brainstorm and list all the failure modes — there could be several for each step. Put each in a separate row in the Failure Mode column.

-

For each failure mode list what is the effect on the customer and the business consequences and enter it in the Effects column. It is likely that many recurring themes will occur with the same effect from many failure modes. Multiple effects may be possible, in which case duplicate the line and enter the additional effect.

-

For each failure mode list the cause of the failure in the Cause column. Using the 5 Whys technique may be helpful to drill down to the root cause.

-

For each failure mode ask "What controls are already in place to prevent escape to the customer?" and write them in the Control column. Don't invent new controls this is a current state analysis. There may be no effective control, in which case write "None".

-

Having completed all the text run the following test on each row (it is easy to get answers inverted or the columns swapped particularly if this is your first attempt at FMEA):

- For each Failure Mode ask:

- What If? It should match the Effect column

- Why? It should match the Cause column

- What Controls? It should match the Controls column

-

Scoring should be completed for each of the Severity, Occurence and Detection columns. First consider all of the effects. Decide which is the most severe and the least severe. You may have a pre-defined severity rating used by your business so use that as a guide. If not score the most severe effect as with the highest number and the least severe effect with the lowest.

-

A 1 to 5 scoring is likely more that sufficient resolution. Some consider Low, Medium, High to be sufficient and score 1, 3, 5 only. A 1-10 scale gives a very high level of precision but will make deciding on a score more difficult.

-

Consider the occurrence of all the causes first. Score the most frequent or likely highest, and the least frequent or likely the lowest. It may be that one of the causes is so unlikely as to be not worth considering. Simply score it 0 to eliminate it from the analysis or consideration.

-

Consider all of the controls. "None" get an automatic 5. Review the others for the probability of escaping detection. High probablities get a 5. Low probablities get a 1. If the only realistic assesment you can make is Low, Medium or High, score 1, 3 and 5 respectively. This will still provide more than adequate resolution.

-

Double check the logic of your control scores. It is easy to invert the scoring system in error. A good control should have a low score. A poor control should have a high score.

-

Mulitply the three scores for the Risk Priority Number (RPN). These can range from 125 to 1, more resolution than you need.

Stage 2 — Assess

-

Set a threshold for your risk mitigation planning. Risks greater than 30 say, may need an action plan. FMEA is not complete until you have reviewed your risk mitigation plan and maybe repeated the FMEA with new revised scores.

-

For each RPN greater than the threshold, review the three scores and discuss opportunities to reduce the highest value. Usually reducing severity is the most difficult while increasing the control is the easiest.

-

Just increasing the control may incur additional cost of process or inspection so it is the least desirable.

-

With the mitigation plan in mind review and revise the three scores to calculate a revised RPN. This represents a potential improvement until the plan is implemented and tested.

-

The Revised RPN may be updated after roll out with real or more precise predictions of the data it embodies

What is FMEA?

FMEA is a process risk analysis that informs process development and improvement and is particularly powerful in developing new business information, and new transactional, manufacturing or assembly processes.

It is used by an improvement team to understand and evaluate potential failures and using that knowledge to plan risk mitigation for future deployment of the process.

FMEA helps by:

- Identifying the potential ways in which a process can fail (also known as "failure modes").

- Assessing the impact or severity of each potential failure.

- Assessing the likelihood or ocurrence of the potential failures.

- Assessing the probability that the failure will be caught internally, a.k.a. detection.

FMEA can be a complex and tricky tool to use.

There are many potential pitfalls. Seek advice from someone with prior experience while you gain knowledge and understanding of the tool.

Free: Lean Six Sigma

Project Template Library

Sign-up for email updates and get:

- Unlimited template library access.

- Microsoft Excel and Google Docs template files.

Plus:

- Subscriber-only course discounts

- Unlimited Free consultation with our Master Black Belt.

- Regular updates, including new articles and free resources.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

LearnSixSigm

LearnSixSigm