Six Sigma Advanced Manufacturing

Tailored Short Course

This course is tailored to your specialist requirements for advanced manufacturing. Depending on your needs it can include:

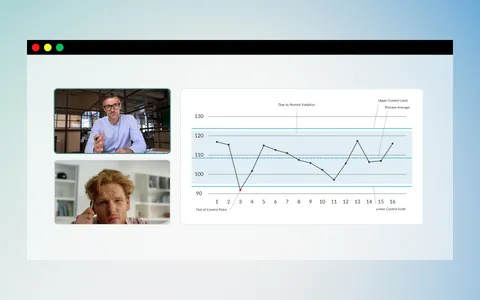

This is about acquiring and visualising the data relevant to your customers and your process. It will include tools for comparing data samples while seeking process improvement including capability analysis against customer specifications. Depending on your prior understanding of the statistics involved it could start from graphical methods, continue to the basics of inferential statistics and extend to Hypothesis Testing, Anova and Regression.

A practical understanding of Measurement Systems Analysis and how to apply it to instrument measurement systems, manual measurements and even human appraisal judgement. It is quite often true that we have a slightly inflated sense of our own capability in achieving our critical process measurements. And as the old saying goes “If you can’t measure it, you can’t control it”

There are two broad fields of problem solving: a number of additive and contributory causes, only one true cause among many possibles. These two cases require very different approaches and start with the simplest team based tools such as Cause and Effect Analysis and The Five Whys and progress to Analytical Root Cause Analysis for complex systems investigation. These tools can stand alone or they can be fitted to the problem identification and resolution step of your existing Defect Elimination strategy such as 8D or A4.

Design of Experiments provides a highly effective and a resource efficient strategy to model a complex process leading to a clear understanding of its main control factors and their optimisation. There are many different orthogonal designs to choose from. This will provide a practical guide to their selection, and a practical approach to their use for both an initial screening experiment and a full modelling experiment.

Two days of practice with the tools for basic analysis of data and sample statistics for Six Sigma.

In this module we will demonstrate and practice the more analytical tools used in Six Sigma projects.

Two days of analytical tools for advanced level Black Belt Six Sigma.

Applicable in precision and high tech manufacturing.

On completion of this course you will be awarded:

On delivery of your certification project you will be awarded:

You'll work through practical project examples to gain hands-on experience of the software and tools by collaborating in a fun and challenging environment.

We'll share 20 years of insight and experience in industry to help you create and deliver your first valuable projects to your business.

Be it a Lean or Six Sigma project you'll need a structured approach to achieve lasting change for your initiatives.

Share ideas and achievements with others, and get valuable feedback on your journey to becoming a Lean Six Sigma practitioner.

Martin qualified as a Six Sigma Master Black Belt in 2002 with Air Academy, Colorado Springs, USA. He has trained over 1200 students and taught courses across the USA, Europe, and Asia.

He worked for global Life Sciences company Perkin-Elmer until 2014 and delivered projects for various domains from business process to scientific instrument manufacture.

Martin lives and works in Buckinghamshire, England.

Sign-up for email updates and access:

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

We'll email you our up to date course prices and dates.

Plus sign-up for updates and get:

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.