What is Takt Time?

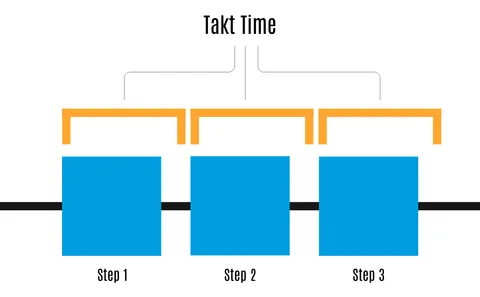

Takt time is defined as: available production time divided by the customer demand that must be met in that period. It's also the target time for the steps in the one-piece flow Lean production method.

How to Calculate Takt Time

Where:

- — Available production time

- — Customer demand to be served during the available production time

Related: Calculator: Takt Time

Single-Piece Flow: Takt time in Lean Production

Knowing the takt time is essential if you're designing a one-piece flow process. The name comes from the German taktzeit (pulse-time) via engineers visiting Japan, eventually finding its way into Toyota. Takt time is the heartbeat of the one-piece flow method.

Example 1: Takt Time Calculation

Let's look at the sandwich counter pictured above. During the busy lunch period at 12pm–2pm they serve 160 customers. We can calculate the takt time as follows:

Available Production Time

Sometimes also called net production time, this must not include non-productive time during the work period, such as breaks or public holidays.

Takt Time vs. Cycle Time

Takt time is often confused with cycle time, but they are very different.

Takt Time is a target we calculate for a one-piece flow production process. Cycle time is the average time it takes to process one product from start to finish.

Why is Takt Time Important?

Takt time gives us a target to design or modify a one-piece flow process so that production units move between process steps and exit the process at the rate of one every takt time. This way customer demand is met and there is no overproduction of the process output.

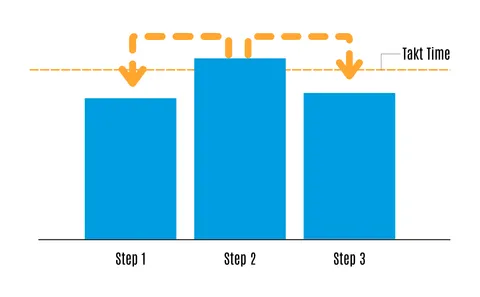

Any step running over will slow down the entire process, and inventory will build up behind it. If the steps run too fast then there will be a surplus of production.

How to Use Takt Time

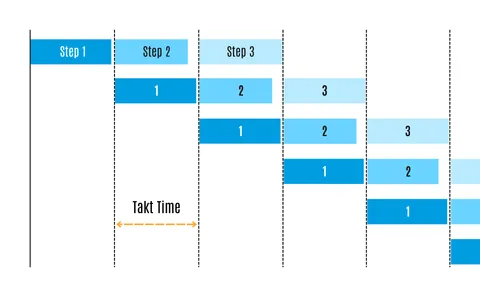

Knowing the takt time will allow us to increase the output of a one-piece flow production process to meet higher demand, and prevent it from overproducing. It also allows us to make an existing process into a one-piece flow, or design a wholly new one.

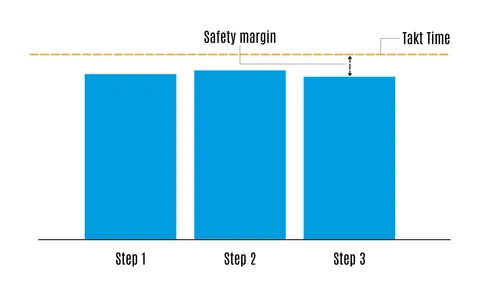

We should break the process down into a series of small tasks fitting into the takt time. Each step in the process should be timed to see how long it takes. If any of the steps take longer than the takt time then we will need to modify our process.

Rebalancing

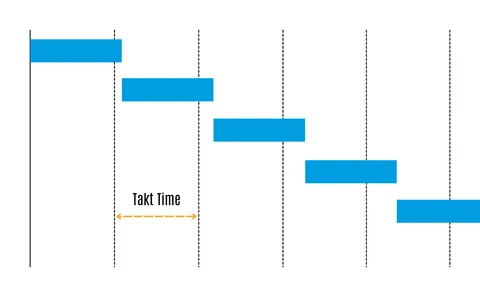

Process steps that run over the takt time can be rebalanced by shifting work into new or existing steps. For human operators it's always necessary to include a little margin in each step as their rate of work will naturally vary.

Example 2: Process Rebalancing

Let's look at the sandwich counter again and time the individual steps used to make a sandwich.

The server must warm the bread, taking 30 seconds, make the sandwich by cutting the bread and filling it, taking 50 seconds, and then wrap and pack, taking 40 seconds.

The first and third steps take less than the takt time but the second step takes 10 seconds longer. We need to find a way to move some of the work to other steps.

While timing the second step we noticed that cutting the bread takes around 7 seconds. Moving cutting to the first step we re-time all three steps to find that they now take 37, 43 and 40 seconds each, all less than the takt time.

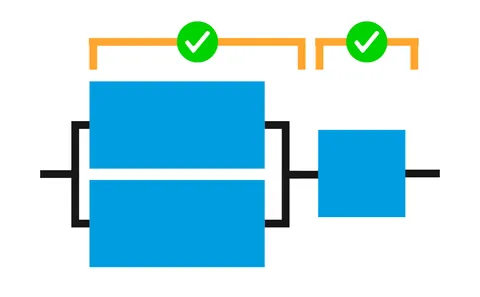

Adding Parallel Steps

If it is impossible to change a process step to fit within the target takt time, another option is to have two parallel workstations, each working to twice the takt time. You may add further workstations in parallel for steps that take even longer.

Example 3: Adding Steps in Parallel

Let's focus on an earlier step in the sandwich process that we left out, where customers place their order and also pay at the cash register.

Say it takes 80 seconds for a customer to place an order and pay. This is more than the takt time of 45 seconds, but less than twice the takt time, or 90 seconds.

Let's also say it's not possible to move tasks from this step. We could then have two cash registers serving two customers every 80 seconds, or one customer per the takt time.

Moderating the flow of units

As takt time is a target and not something that can be exactly acheived, methods of slowing production will also need to be added to keep the process moving at the ideal pace.

The Kanban is a visual management tool that can be very useful in this regard.

Example 4: Kanbans

Next to each of the operators in our sandwich process from before there is a space on their left from which he or she takes the next item to be processed.

When the operator has finished an item they place it on their right, but only if the space is empty. If the space is full, they stop working until the space is empty again.

Equally if there is no item waiting to be processed on their left, they also stop working until one arrives.

This Kanban helps to moderate the pace of production and keep things moving evenly through the process.

Benefits of Using Takt Time Effectively

Reduced lead time

With one-piece flow orders spend minimal time in production as there is little to no waiting between steps in the process. This reduces lead times, improving customer satisfaction.

Greater detection and reduced impact of defects

Since the focus of work is on single units, defective items can be removed quickly with minimal impact on production, and issues can be remedied before more units are affected.

As each operator in a one-piece flow process has a clear role, they will quickly spot and potentially fix defects that affect their ability to complete their work.

Reduced inventory

Storing inventory is a cost to any business. This can include units waiting for production, customers waiting to be served, or excess production at the end of a process.

With one-piece flow, all these opportunities to accumulate inventory are mitigated, if not eliminated.

Reduced floorspace and travel time

Because of the reduced inventory of units waiting for processing, production lines can be built in a smaller area, reducing space costs and reducing the labour from units travelling between process steps.

Contrast this with a batch process where large amounts of units in progress need to be moved around and stored.

Reduced training costs

Since operators in a one-piece flow process have a specific task, the initial cost of training them will likely be reduced.

Limitations of Using Takt Time

Inflexible to changes in customer demand or available production time

In reality businesses will use an estimate instead of actual customer demand, which fluctuates. There will always be some unmet demand or excess inventory

While you can make every effort to ensure production is not interrupted, unanticipated downtime or stoppages are always possible.

Sensitive to operator availability and morale

One-piece flow processes require many operators. If operators become unavailable, the entire process will stall. The greater the number of operators, the higher the chance of unavailability.

Sensitive to operator morale

Operator morale can suffer due to the monotonous nature of the work. Retraining and moving operators to another part of the the process can help.

LearnSixSigm

LearnSixSigm